Welcome to website!

Welcome to website!

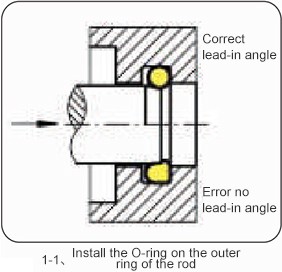

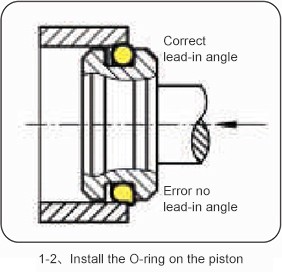

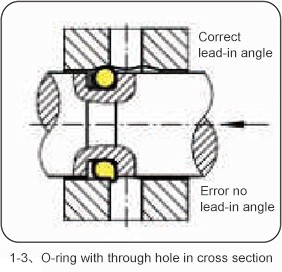

Is the lead-in angle processed according to the drawing?

Is the inner diameter deburred? Is the sharp edge rounded?

Have processing residues, such as chips, dirt, foreign particles, etc., been removed?

Is the thread tip covered?

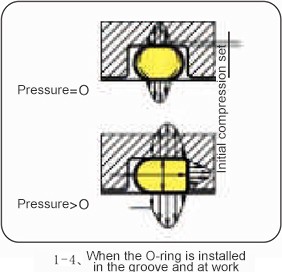

Have the seals and parts been greased or lubricated (Ensure the medium compatibility with the elastomer. It is recommended to use the sealed fluid for lubrication.

Do not use grease containing solid additives, such as molybdenum disulfide and zinc sulfide.

Use tools without sharp edges;

Ensure that the O-ring is not distorted, and use auxiliary tools to ensure correct positioning;

Try to use installation aids;

Do not stretch the O-ring excessively;

For O-rings bonded with sealing strips, they must not be stretched at the joints.

When the O-ring is stretched to pass through threads, splines, keyways, etc., a mounting mandrel must be used. The mandrel can be made of softer metal or plastic without burrs and sharp edges.

Automated installation of O-rings requires adequate preparation. Usually the surface of the O-ring is treated in several ways, which has reduced the installation friction, prevents adhesion, and is easy to separate.

For the handling and installation of parts with unstable dimensions, a wealth of experience is required. To obtain reliable automated assembly, special operation and installation of O-rings are required.