Welcome to website!

Welcome to website!

The initial deformation (squeeze amount) of the O-ring in the full groove is necessary for its sealing effect:

1. Obtain the initial sealing contact stress

2. Compensate product tolerances (connect the two in a clearance fit);

3. Guarantee-fixed friction;

4. Compensation for permanent compression deformation (loss);

5. Compensation for wear.

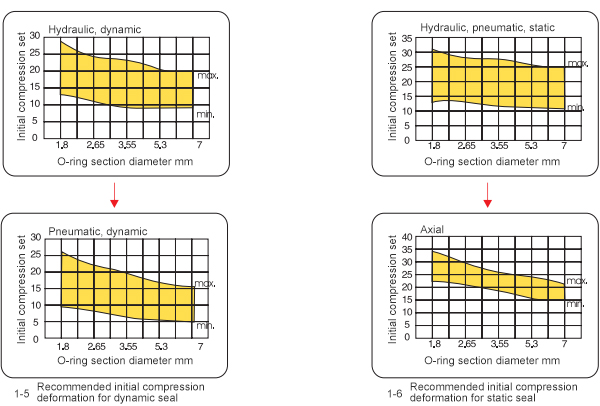

For different applications, the ratio of the initial deformation to the cross-sectional diameter (d2) is listed below;

Dynamic sealing application: 6%-20%

Static sealing application: 15%-30%

When designing, the groove size can be designed according to the recommended initial compression deformation in Figure 1-5 and Figure 1-6:

The initial compression deformation in the above two figures is made according to the ISO3601-2 standard, with reference to the relationship between the load and the cross-sectional diameter.

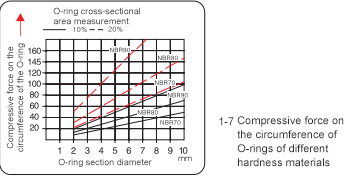

Due to the difference in the degree of initial deformation and the hardness of the sealing material, the compression pressure of the O-ring is also different.

Figure 1-7 shows the compression force per centimeter of the O-ring circumference. This graph can be used to estimate the total compressive force experienced by the O-ring during static sealing applications. Tension and compression are two forms of installation of O-rings in grooves. In the radial seal configuration, the O-ring is installed in the inner groove (as an "external seal"), the O-ring must be stretched, and its inner diameter is greater than the outer diameter of the groove after being stretched. After installation, the maximum elongation of the O-ring should be 3% (inner diameter>50mm) or 5% (inner diameter<50mm).

When the O-ring is installed in the outer groove (as an "internal seal"), the O-ring is compressed along the circumference of the circumference. In the installed state, the maximum perimeter compression is 1%. If the amount of tension or compression exceeds the above, it will cause an excessive increase or decrease in the cross-sectional size of the O-ring, which will lead to the working life of the O-ring. An O-ring stretched by 1% along the circumference will cause its cross-sectional size to shrink by 0.5%.